Business information shows that, as of June 5, 2020, the number of suspended and cancelled enterprises whose business scope contains the keyword "meltblown fabric" reached 45. The number of suspended and cancelled enterprises whose business scope contains the keyword "mask" is more than 10,000. With the stabilization of the epidemic, the meltblown fabric market is facing a reshuffle.

In the context of economic globalization, the international market not only has level requirements for salt index of meltblown fabric, but also sets the threshold for oil index, which is the current difficulty of the meltblown nonwoven fabric market. European EN149: 2001 + A1 2009 "respiratory protection device particle protection with filtration half mask requirements inspection and marking" standard, which FFP2 and FFP3 standards for NaCl particles and paraffin oil particles, both filtration requirements (flow rate of 95L / min).

FFP2: oily particles filtration efficiency > 94%, salt filtration efficiency > 94%

FFP3: Oil particles filtration efficiency>99%, salt filtration efficiency>99%

Based on the above, since the introduction of meltblown cloth production line, Yuanchen Technology has continued to optimize and adjust the process and analyze the quality determining factors of meltblown cloth: equipment, process, meltblown material, electret equipment and process, and electret masterbatch. Finally, we have determined three major hard conditions to improve the efficiency: one is the raw material melt index (MFI); the second is the electret treatment process; and the third is the suitable pore size ratio meltblown mold.

01 dedicated raw material melt index (MFI)

The lower the molecular weight of the polymer, the higher the melt flow index (MFI), the lower the viscosity of the melt, the more suitable for the meltblown process weaker draw action. Small molecular weight, good flow performance, high melt index. The melt index reflects not only the flowability of the polymer itself, but also the physical and mechanical properties of the fiber and fiber network made of it are closely related. The crystallinity and orientation of meltblown fibers are smaller than those of spunbond. Therefore, the strength of meltblown fibers is poor, so the strength of the fiber network is also poor. Under the same process conditions of screw speed, PP chips with high MFI can increase the output by 1/3; as the hot air temperature can be reduced, the energy consumption is also reduced accordingly.

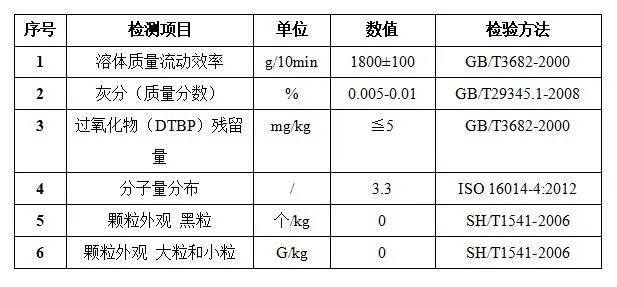

Table 1 Raw material performance parameters

02 High frequency constant voltage + constant current needle electrostatic bar + electrostatic electret equipment

1, electrostatic electret using high-frequency design rather than the market's common frequency regulator multiplier, electrostatic output is stable within 1% and small ripple, combined with the constant current output of the electrostatic bar, so that the meltblown fabric surface electrostatic distribution evenly, thereby controlling the PFE CV value volatility;.

2, the use of needle-type electrostatic bar, you can polarize the ion, through the acceleration voltage, the negative (positive) charge along the needle tip direction (vertical direction), directly on the meltblown cloth to produce the corona effect and resides in the molecular layer, thus ensuring that the PFE stable non-decay.

3, each set of electrostatic electret equipment factory after strict calibration and give the best distance, voltage and current value, easy to learn, beginners can also debug, will not produce sparks, can feel the strongest ion wind, the dark state can see the uniform blue light, so as to achieve the best electret effect.

03 suitable aperture ratio meltblown mold

The meltblown process is much smaller than the diameter of the spinneret used in the inner and outer layers of spunbond because the meltblown fiber diameter is only one tenth of the spunbond fiber. The meltblown polymer pellets are fed by a screw extruder to the meltblown die assembly, which includes the polymer distribution system, the die system, the draft hot air line channels and the heating and insulation elements, and are extruded through the spinneret holes in the die.

In order to achieve the required fineness, in addition to relying on smaller spinneret holes, the extrusion of the spinneret holes while subjecting the melt fibers to high speed hot air flow drafting on both sides, in addition to the room temperature air on both sides mixed with hot air flow, can make the melt being drawn fine cooling and curing into shape. However, many spinneret molds on the market are not standard materials, with some low-end mold steel instead, the use of the process will appear some eyes can not see the fine cracks, aperture processing rough, poor precision, without polishing treatment, directly on the machine. Resulting in uneven spinnerets, poor toughness, spinnerets of varying thickness, easy to produce crystallization. Our company through long-term experimental data comparison tracking, the use of foreign imported molds to select the optimal mold aperture and hole spacing, can be stable production of 25 grams of FFP2 filter efficiency meltblown cloth.

China's meltblown fabric manufacturing industry has been rising rapidly in recent years. In 2020, influenced by the epidemic, the domestic mask industry is in shortage of raw materials, and Yuanchen Technology urgently prepares to build a meltblown nonwoven fabric production project with an annual output of 1,000 tons to join the epidemic prevention and control blocking war with practical action.

Yuanchen Technology always insists on the development driven by scientific and technological innovation, pays attention to the construction of scientific research and industrialization of technical achievements, builds key laboratories and R&D centers for meltblown fabrics, and exports its products to Japan, Korea, Germany, Israel, the United States, Britain, Lithuania, France, Canada, Austria, Romania, Australia and other countries and regions. In the future, we will continue to serve the strategic needs of each country, aim at the frontier of world science and technology, and write a new chapter for the innovative development of meltblown fabric industry.