This report comes from the Polaris Environmental Protection Network: According to the China Environmental Protection Industry Association desulfurization denitration committee statistics, the national thermal power plants have been put into operation flue gas desulfurization denitration unit capacity accounted for more than 90% of the national coal power unit capacity, ordinary desulfurization denitration transformation has been close to saturation, thermal power air treatment "ceiling" is emerging. The Ministry of Industry and Information Technology Sadie Research Institute research report pointed out that the current thermal power industry to further reduce pollutants face diminishing marginal space, the marginal cost of rising constraints, the focus of air pollution prevention work should be shifted to non-electric industries with higher pollutant emission intensity.

In June 2017, the Ministry of Environmental Protection issued a revised list of 20 national pollutant emission standards, including "air pollution emission standards for iron and steel sintering and pellet industries", modifying the special emission limits for iron and steel sintering and pellet air, and adding special emission limits for flat glass, ceramics, and brick and tile industries. 25 April 2018,Hebei Province released five non-electric industries, including iron and steel, coking, cement, flat glass, and boilers On April 25, 2018, Hebei Province released the draft of air pollution emission standards for five non-electric industries, including steel, coking, cement, flat glass and boilers. On May 7, 2018, the General Office of the Ministry of Ecology and the Environment issued a letter to seek comments on the "Iron and Steel Enterprise Ultra-low Emission Reform Work Program (Draft for Comments)", which mentioned that the hourly average emission concentrations of particulate matter, sulfur dioxide, and nitrogen oxides are not higher than 10, 35, and 50 mg/m3, respectively. , 35, 50 mg/m3. With the government's increased emphasis on non-electric industrial air pollution emissions, the non-electric industrial sector will become the next windfall for air pollution treatment in the context of the near saturation of the power industry's desulfurization and denitrification market.

On May 17, 2018, the 2018 Symposium on Flue Gas Treatment Technology and Application in Iron and Steel and Coking Industry, hosted by Polaris Environmental Protection Network, co-organized by Siboying, and supported by Tsinghua University-National Engineering Laboratory of Flue Gas Multi-Pollutant Control Technology and Equipment, National Environmental Protection Mercury Pollution Prevention Engineering Technology Center, and North China Electric Power University, was held in Tangshan, Hebei, China, with the Ministry of Ecological Environment, the China Academy of Environmental Sciences, Metallurgical Industry Planning and Research Institute, metallurgical design institutes, steel enterprises, coking enterprises, flue gas treatment environmental protection enterprises and other more than 400 people participated in the meeting to discuss the policy standards, technical difficulties, project applications and other hot topics of flue gas treatment in the iron and steel and coking industries, and to contribute to better solve the problem of flue gas treatment in the iron and steel and coking industries. Xiong Huawen, Deputy Director of Energy Efficiency Center of Energy Research Institute of National Development and Reform Commission, hosted the conference and delivered a speech.

Xiong Huawen, Deputy Director, Energy Efficiency Center, Energy Research Institute, National Development and Reform Commission

Policy forced steel coking industry flue gas treatment has been in the wind

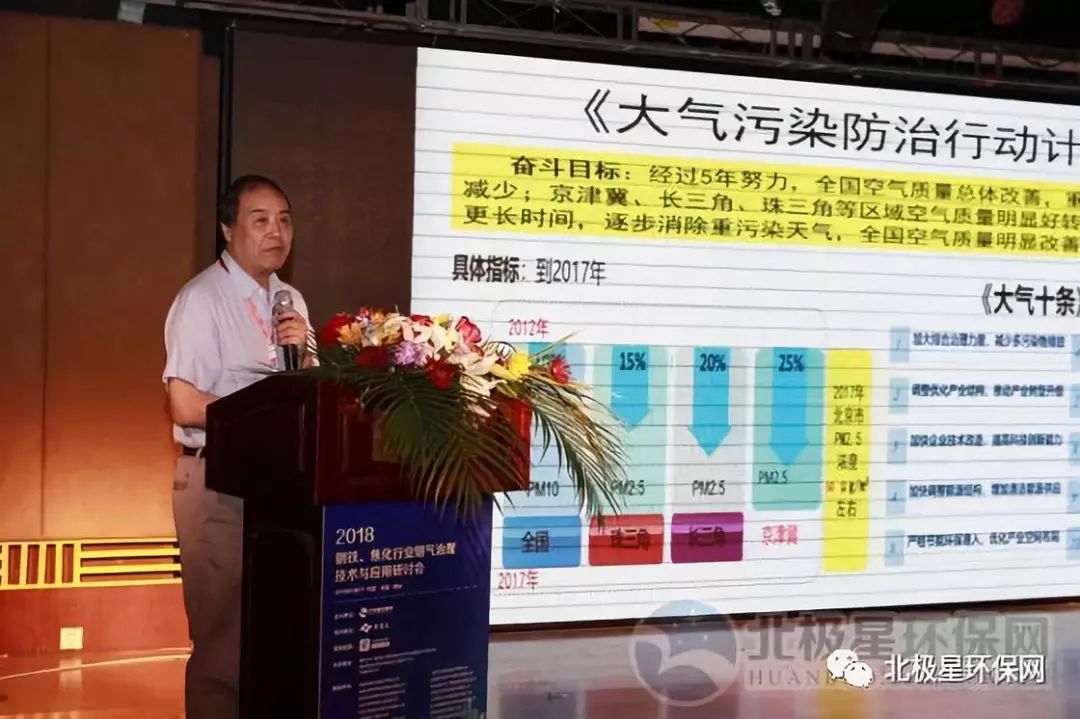

In addition to the power industry, the industrial sector coal consumption of large areas were steel, cement, metallurgical coking, coal chemical industry, industrial boilers, industrial kilns. The state and several provinces and cities are paying more and more attention to the treatment of iron and steel flue gas. Chai Fahe, chief scientist of the Chinese Academy of Environmental Sciences for atmospheric environment, proposed: the steel industry is a relatively large national pollutant emissions industry, as a large steel province, Hebei Province, steel emissions is a focus of air pollution prevention. The country's air pollution control of the steel industry to take a comprehensive approach. Hebei iron and steel ultra-low emission draft, the requirements of the iron and steel industry emission limits, is the first time to put forward to the iron and steel industry ultra-low emission requirements. These requirements are not only for particulate matter, sulfur dioxide, nitrogen oxides to put forward specific emission control requirements, and multi-pollutant synergistic control also put forward requirements, especially for other major pollutant emissions, sulfuric acid, etc. also put forward the same requirements, while the disorganized emissions also put forward requirements. Hebei steel ultra-low emissions is the concept of all-round, whole process control.

Chai Fahe, Chief Scientist of Atmospheric Environment, Chinese Academy of Environmental Sciences

In November 2016, the General Office of the State Council issued the Implementation Plan for the Pollutant Emission Control Permit System (Guo Ban Fa [2016] No. 81), which clearly builds an environmental management system for stationary pollution sources with the emission permit system as the core, and carries out the issuance of emission permits covering all stationary pollution sources. Du Yunhui, Director of the Emission Permit Technical Department of the Environmental Engineering Assessment Center of the Ministry of Ecology, gave a detailed introduction to the progress of the implementation of the emission permit system from four aspects: the overall design of the emission permit, the technical system of the emission permit, the progress of the emission permit work, and the requirements for enterprises to respond to it. She believes that in order to cope with the requirements of the emission permit system, enterprises should do the following two things: Firstly, each enterprise should study laws and regulations, management methods and self-testing guidelines, etc., and master environmental knowledge. The second enterprise to do a good job of physical examination. Sort out the discharge of various pollutants in water and gas, and establish countermeasures.

Du Yunhui, Department of Pollution Permit Technology, Environmental Engineering Assessment Center, Ministry of Ecology and Environment

In the face of such a serious environmental situation, Liu Tao, director of the Environmental Protection Center of the Metallurgical Industry Planning Institute, gave advice: the biggest is the change in concept. Should recognize that environmental protection is not just spending money, but actually have a benefit. Environmental protection can both force companies to achieve environmental protection, improve corporate management, and reduce the risks associated with environmental management policies.

Liu Tao, Director of Environmental Protection Center, Institute of Metallurgical Industry Planning

Complex working conditions How to crack the difficult governance?

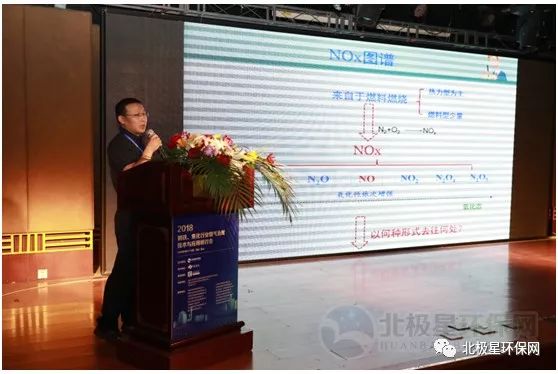

At present, there are diverse technologies in the non-electric industry, how to achieve real emission reduction? Li Junhua, professor and doctoral supervisor of School of Environment, Tsinghua University, gave a demonstration of pollutant emission reduction targets and advanced treatment technologies in the non-electricity industry. Li Junhua introduced the overall situation of air pollution and analyzed the main technical routes of air pollution in non-electric industries.

Professor and Doctoral Supervisor, School of Environment, Tsinghua University, Li Junhua

Steel and coking flue gases have diverse compositions and complex working conditions, and environmental protection companies have given precise treatment technologies. Ltd. introduced the low temperature flue gas denitrification process route and some progress in new catalysts. Sparking has developed a manganese catalyst. The manganese catalyst can ensure stable operation at 230 degrees Celsius against the heavy influence of no more than 500 mg of sulfur dioxide. This has been proven through extensive engineering practice.

Zhang Xianlong, Technical Consultant, Hubei Siboying Environmental Protection Technology Co.

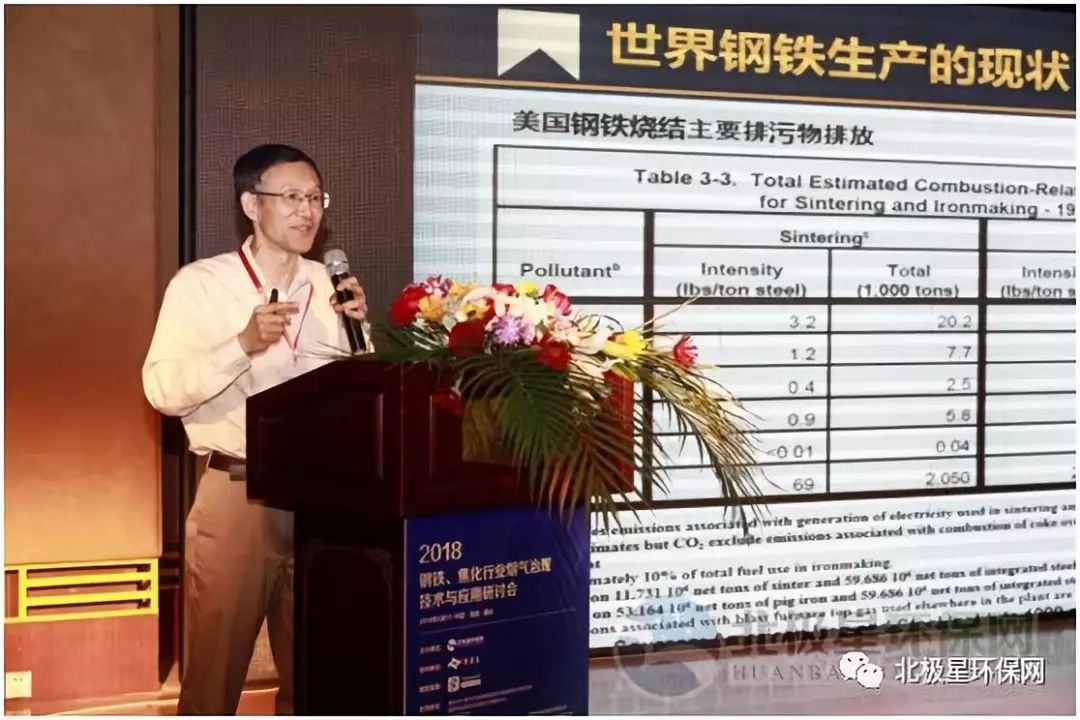

Professor Chen Yongsheng from the Department of Environmental and Civil Engineering, Georgia Institute of Technology, USA, introduced the situation and treatment technologies related to emissions from the US steel industry, which provides a reference for the treatment of the steel industry.

Chen Yongsheng, Professor, Department of Environmental and Civil Engineering, Georgia Institute of Technology, USA

With the promotion of environmental management in steel and coking, the integrated technology of desulfurization and denitrification has become the development direction. In this regard, Jiang Chiguang, deputy general manager of Zhongjing Environmental Technology Co., Ltd. introduced the FOSS integrated desulfurization and denitrification near-zero emission technology and application introduction. At present, there are three main ways of sinter denitrification, activated coke or activated carbon, SCR denitrification and oxidation denitrification. There is no one method which is perfect, all three ways of denitrification have their own advantages and disadvantages, each steel mill should consider their own situation carefully and make an effective choice. In line with the concept of circular economy to control pollution, Zhongjing Environment has developed FOSS desulfurization and denitrification integrated near-zero emission technology, which has been applied in Tangshan Delong and Xingtai Delong.

Jiang Chiguang, Vice President of Zhongjing Environmental Technology Co.

Diverse technologies, environmental protection enterprises show their skills

By the end of 2016, there were 1,420 coke ovens in China, of which 12.3% were at the leading international level, 39.2% were at the advanced domestic level and 48.1% were at the general level. 48.1% were mainly 4m3 coke ovens. As a big coke country, what is the current situation of coke flue gas treatment in China? Zheng Wenhua, technical advisor of Zhongyue Coke & Nai (Dalian) Engineering Technology Co., Ltd, introduced three technologies, a dry desulfurization plus SCR denitrification used in large coke plants, the second semi-dry desulfurization and denitrification of Baosteel Zhanjiang SDA, and the third low-temperature SCR plus ammonia desulfurization of Shougang Jingtang, and compared several technologies.

Zheng Wenhua, Technical Consultant of CMC Journai (Dalian) Engineering Technology Co.

This year, many local governments issued policies requiring steel enterprises to carry out white smoke treatment. The most important thing for white smoke control is to understand the causes of wet plume and countermeasures for control. Zhu Yeqing, director of the marketing department and deputy director of the design center of the Institute of Environmental Engineering of Guodian Environmental Protection Research Institute, said that the main factor affecting the smoke plume emission is the ambient temperature, the lower the ambient temperature, the more difficult it is to manage. Second is the wind speed, the higher the wind speed, the farther it floats. The third is the load, the full load situation flue gas speed is a little faster. The three main technical routes are direct heating, the second cooling, the third is cooling reheat. Now many technologies are derived from this basis.

Director of Marketing Department and Deputy Director of Design Center, Institute of Environmental Engineering, Guodian Environmental Protection Research Institute Zhu Yeqing

For the technology of steel flue gas desulfurization and denitrification, Lu Qiang, Deputy Director of National Engineering Laboratory of Biomass Power Generation Equipment, North China Electric Power University, and Li Xiang, General Manager of Metallurgical Environmental Protection Division, Jiangsu Kexing Environmental Protection Co. The two major technical difficulties of low temperature denitrification are the reduction of low temperature denitrification catalyst activity and the misfire of catalyst. How to solve these problems is a test for denitrification catalysts.

In response, UWEC has developed an alkali metal resistant catalyst. This catalyst allows the alkali metal to be accommodated inside the pore, minimizing the surface adsorption of alkali metal, which improves the catalyst's resistance to alkali metal poisoning and indirectly enhances the denitrification rate.

Lu Qiang, Deputy Director of National Engineering Laboratory of Biomass Power Generation Equipment, North China Electric Power University

Li Xiang, General Manager of Metallurgical Environmental Protection Division of Jiangsu Kexing Environmental Protection Co., Ltd. introduced the technology of Kexing Environmental Protection. Kexing's activated carbon technology not only realizes the coordinated treatment and resource utilization of multiple pollutants in flue gas, treating heavy metals such as sulfur, nitrate and dust down through activated carbon, the flue gas evolution system is safe and controllable, but also reliable, safe and high efficiency, with desulfurization reaching 99.5% and denitrification efficiency greater than or equal to 85%, and to be stable for a long time. Li wants to say that Kexing Environmental Protection Company has reliable technology and is willing to provide quality service for the owner.

General Manager of Metallurgical Environmental Protection Division, Jiangsu Kexing Environmental Protection Co.

Ltd. analyzed the development and application of dry ultra-clean technology for sintering (pellet) flue gas, Zheng Jinlang mentioned that from the development of indicators, from the beginning of the total amount of control to quality control, the progression of environmental quality control is obviously a trend, and the European and American countries are also the ultimate capacity of the environment to determine the entire economic development. The COA investment is only one third of the cost of the original desulfurization and dust removal, and the operating cost is only one third. Zheng Jinlang also showed us the successful application projects of COA.

Fujian Longjing Desulfurization and Denitration Engineering Co.

Ltd. Wang Guangying explained the analysis of denitration catalyst application technology, Anhui Yuanchen is mainly engaged in dust removal and catalysts, and has made great efforts in the introduction of talents and software and hardware additions in the past few years, and the new products have obtained national certification. The company has the qualification of catalyst regeneration, the company's philosophy is to let our catalysts serve for three years and then serve for three or six years, through the way of Yuanchen environmental protection to ensure a longer life of catalysts.

Anhui Yuanchen Environmental Protection Technology Co. Ltd. General Manager of Catalyst Division Wang Guangying

Chen Wuhu of China Baowu Design Institute made a report entitled "denitrification and application of sintering pellet flue gas denitrification technology in steel industry". Chen Wuhu introduced that the current sintering machine is 600 sets of national statistics from about 2015, and now there are some changes, about 20% are semi-dry series, and the rest are dry method. Since the sintering machine has been running for such a long time, the main problems faced by the sintering desulfurization and denitrification dust removal are sulfur dioxide, nitrogen oxides, dust, gypsum rain, etc. Chen live tiger from a number of aspects of sinter pellet flue gas desulfurization denitrification de-white process technology to analyze.

China Baowu Design Institute Shanghai Baosteel Energy-saving and Environmental Protection Technology Co., Ltd. Director of Environmental Protection Division Chen Wuhu

Prof. Guo Chao, General Manager of Wuhan Sky Blue Environmental Protection Technology Co., Ltd. shared "Application of Fine Particle Agglomeration Enhanced Dust Removal Technology in Industry". Guo Chao mainly introduced a technology promoted and applied by the Ministry of Industry and Information Technology - fine particle agglomeration enhanced dust removal technology. Guo Chao mentioned that Sky Blue is a technology company specializing in haze atmospheric treatment and application, and has developed the gas particle agglomeration strengthening technology, which is strongly supported by 863 and 973 projects from the Ministry of Science and Technology of China during the development process, and has also attracted the attention of national leaders and made instructions, and this technology is now widely used in electric power, building materials and metallurgy.

Wuhan Sky Blue Environmental Technology Co., Ltd. Professorial Senior Engineer General Manager Guo Chao

The conference will continue on the 18th, see you soon!