The project design

System to effect

Maintenance instructions

Free testing

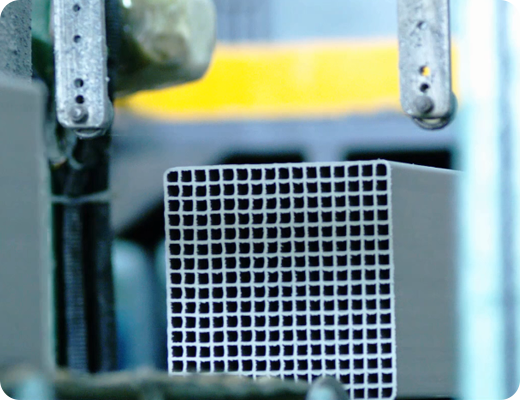

Yuanchen environmental protection mastered the core technology - VOCs catalyst

VOCs catalytic combustion catalyst is the most efficient catalyst for organic waste gas purification with cordierite as the carrier and precious metals and rare earth elements as the main active ingredients; it is prepared and shaped by the unique method of high dispersion rate and uniform distribution. It is suitable for the purification of benzene, lipids, ketones, alcohols, straight-chain alkanes, DMF, AMP, etc. toxic exhaust gases emitted from pharmaceutical, chemical, food, machinery, instrumentation, household appliances, paint plating, printing, color steel manufacturing, smelting and other industries, and the purification effect can reach 98%. According to different working conditions, different exhaust gas components and concentrations, we can use different catalysts to reduce customer's cost and improve purification efficiency.

System Composition

The catalytic combustion device is mainly composed of pretreatment system, adsorbent tank or rotor, flame arrestor, heat exchanger, preheating chamber, catalytic bed, fan and electric control cabinet, etc.

Features and advantages of the device

1、Improve the combustion process, low starting combustion temperature, fast reaction rate; save energy.

2, wide range of application, catalytic combustion can treat almost all hydrocarbon organic waste gas and malodorous gases.

3, for organic chemicals, coatings, insulation materials and other industries emitting low concentration, multi-component, and no recovery value of the exhaust gas, the use of adsorption of a catalytic combustion method of treatment effect is better, economic and reasonable.

4、High processing efficiency, no secondary pollution. The purification rate of exhaust gas is above 95%, and the end products are mainly CO2 and H2O.

VOCs catalyst characteristics

Compared with thermal combustion method, catalytic combustion requires less auxiliary fuel, low energy consumption and small size of equipment and facilities. rco has the characteristics of RTO (regenerative thermal incinerator) for efficient energy recovery and the advantages of low temperature working of catalytic reaction, placing the catalyst on the top of the heat storage material to make the purification optimal, and its heat recovery rate is up to 95%.

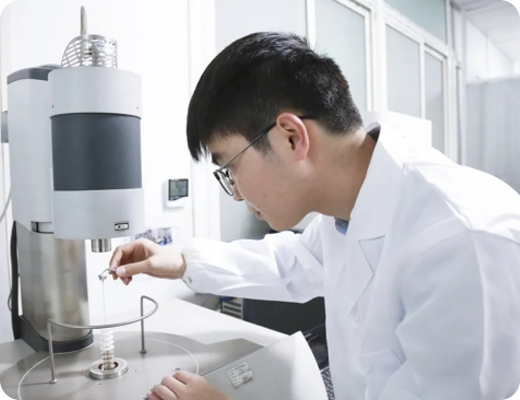

Using Japan's advanced production technology, according to the domestic coal quality and flue gas characteristics of optimization and upgrading, combined with independent research and development, the production of domestic different conditions of flue gas denitrification catalyst

By comparing catalyst composition, compressive strength, specific surface area, pore size analysis and activity detection in CNAS testing center, the cutting-edge catalyst performance enhancement technology with high activity, high wear resistance and high specific surface area was introduced