Dust filter bag (dust bag) is an important part of dust management in the flue gas, and is also the key to the bag filter, often described as the heart of the bag filter.

Dust filter bag (dust bag) filtration principle is mainly the use of filter cloth fiber inertia role of the dust particles in the air intercepted on the surface of the bag, and the use of cloth bag dust collector blowing dust system regularly on the surface of the bag through the dust cleaning device to remove and fall into the dust hopper, and then through the ash discharge system.

Since the use of fiber inertia, the choice of raw materials for dust filter bags (dust bags) is related to the efficiency of dust filtration. Commonly used filter bag raw materials are mainly fluoromethic, P84, PTFE, acrylic, aramid and a variety of fiber blends. And the choice of raw materials depends mainly on what kind of flue gas working conditions.

In the previous article, we have introduced the applicable working conditions and performance characteristics of Fluorometh and P84 dust filter bag (dust bag), and today we will continue to explain the performance of PTFE dust filter bag (dust bag).

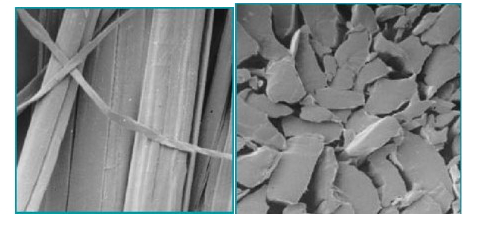

PTFE is polytetrafluoroethylene, fiber color is divided into white and brown, the main reason for this difference is the difference in spinning method.

The difference between white fiber and brown fiber

(1) White fiber is more pure, and the fiber shape is mostly flat type. It is produced by membrane splitting method, so it is more discrete in fineness, generally from 2dtex to 10dtex.

(2) brown fiber will contain a small amount of impurities, fiber shape is mostly round type. Using the wet spinning method so the fiber fineness is relatively fixed, currently 3.3dtex abroad, domestic due to the single yarn strength problems generally in 4dtex or more. Length is generally in 51mm~75mm.

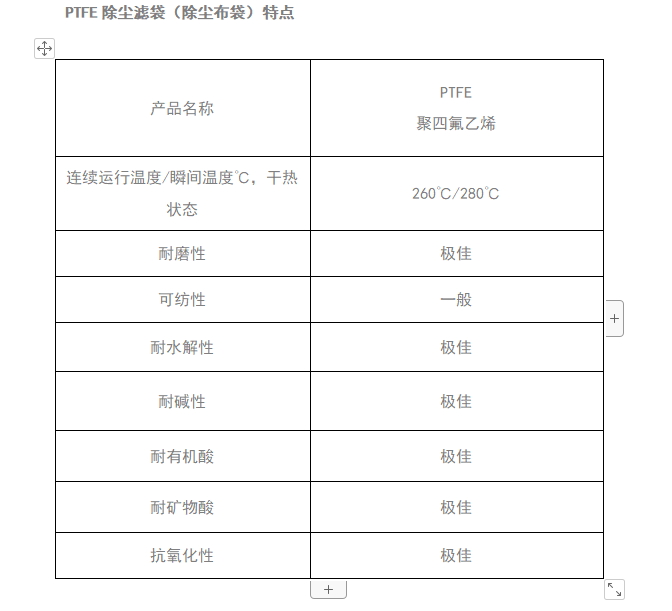

PTFE fiber characteristics

1)Melting point is 327℃, can be used for a long time at 260℃, and the instant use temperature can exceed 300℃.

It cannot be burned, and its ultimate oxygen index reaches 95%.

(2) low strength, elongation at break is small, the breaking strength of imported brown fiber is only 1.9cn/dtex, and the strength of white imported fiber is basically not more than 4cn/dtex.

(3) low coefficient of friction, so dust is easy to fall off on the surface of the filter media.

(4) The fiber surface tension is large, and it has good water repellent performance.

(5) The fiber is fine, the filtration efficiency is general, and the gram weight of the filter media is 750-800g.

(6) Poor textile performance, low holding force, easy to generate static electricity in the fiber textile process.

Anhui Yuanchen Environmental Technology Co., Ltd (hereinafter referred to as "Yuanchen Technology") is a high-tech enterprise integrating R&D, production and sales of dust removal bags and denitrification catalysts. Over the past sixteen years, Yuanchen Technology has been focusing on the environmental protection field, and now has 4 international PCT, 33 authorized invention patents and 77 invention patents in process, among which many products such as "dust removal and denitrification integrated technology products" have been awarded the Scientific Progress Award of Anhui Province. Our dust removal bags (mainly PPS, PTFE, P84 and composite series filter needle felt) and SCR denitrification catalysts have been widely used in cement, steel, glass kilns, waste incineration power generation, biomass power generation, non-ferrous metal smelting and other industries. In the future, Yuanchen Technology will be guided by "becoming the guardian of global ecological environment", always rooted in environmental protection, and insist on the great cause of guarding the blue sky and white clouds. Leveraging on the national ecological civilization construction pattern, we will continue to deepen technology, optimize management, strengthen brand, refine industry and solidify advantages, and create synergistic value for industry through comprehensive and integrated governance and services.