SNCR denitrification technology is also known as selective non-catalytic reduction denitrification technology because no denitrification catalyst is used in the whole reaction process.

In the previous article, we have introduced the composition and influencing factors of SCR denitrification system, so what are the components of SNCR denitrification system and what factors affect its denitrification efficiency?

I. System Composition

SNCR denitrification system generally consists of receiving and storing the reductant; injecting diluted reductant at a suitable location in the boiler; metering output of the reductant, mixing with water for dilution; and mixing the reductant with flue gas for denitrification reaction.

1、Reductant storage and preparation system

This system mainly consists of two major parts: urea dissolution tank and urea solution storage tank. Firstly, urea is added in the dissolution tank and made into a pre-set proportion of urea solution through the mixer, which is transported to the storage tank through the circulation transfer pump. The storage tank and pump station module can be installed in the ammonia area, and the breathing hole is installed at the top of the tank to avoid overpressure or vacuum in the tank.

2、Conveyance distribution metering system

The manufactured reductant is transported to the metering and distribution module through the reductant conveying module. The control system automatically calculates the required amount of reductant according to the flue gas composition obtained from the flue gas, and accurately distributes the required amount of reductant to the injection system through the metering and distribution module.

3、Injection system

The system mainly consists of a two-fluid spray gun, check valve, ball valve and other components, because it is sprayed in the furnace, so the material of the spray gun and the nozzle corrosion resistance has high requirements.

Second, the factors affecting the efficiency of SNCR denitrification

The three most important factors affecting SNCR process are: mixing of reducing agent and flue gas, reaction temperature and residence time.

1、The degree of mixing of reactant and flue gas

One of the main reasons for low SNCR denitrification efficiency is the mixing problem, for example, the local NOx concentration is too high and cannot be reduced by the reductant, resulting in low denitrification efficiency; the local NOx concentration is too low and the reductant is not all reduced, resulting in low reductant utilization and Increase ammonia escape.

2、Temperature range

The reduction reaction of NOx occurs in a specific temperature range, because SNCR does not use catalysts, so a higher temperature is required to ensure the reduction reaction (SNCR reaction temperature range of 850 ℃ ~ 1150 ℃).

If the temperature is too low, it will lead to incomplete NH3 reaction, forming the so-called "ammonia penetration" and increasing the amount of NH3 escaping to form secondary pollution; as the temperature increases, the molecular movement is accelerated, and the evaporation and diffusion process of ammonia is strengthened, for SNCR, when the temperature rises above 800℃, the chemical reaction rate is obviously However, as the temperature continues to rise, the oxidation reaction between NH3 and O2 will intensify after it exceeds 1200°C, generating N2, N2O or NO, increasing the concentration of NOx in the flue gas and decreasing the denitrification rate.

3、Reductant type

Various substances containing amino groups and decomposing when heated to release NH3 can be used as reducing agents for SNCR reaction, among which the most commonly used reducing agents are ammonia and urea.

4. The reductant residence time

Under the same conditions, the denitrification effect is better with longer reductant residence time. In this time, NH3 or urea and other reducing agents and flue gas mixing, evaporation of water, the decomposition of reducing agents and NOx reduction and other steps must be completed, the general requirement of time for 0.5s, urea ammonia residence time is generally between 0.3-0.5s.

5. ammonia to nitrogen ratio (NSR)

That is, the molar ratio of ammonia to NO in the reaction, according to the SNCR reaction, the reduction of 1 mol NO requires 1 mol ammonia or 0.5 mol urea, but in practice the amount of reducing agent than this amount, because the actual reaction is more complex, and the gas mixture is not uniform, to achieve a better denitrification effect must increase the amount of reducing agent. However, experiments show that when the NH3/NO ratio reaches above 2.0, the NO removal rate curve becomes significantly slower, and the NH3/NO ratio is too large, which will cause the increase of ammonia escape, resulting in pollution and higher cost, and the NSR of SNCR is generally controlled at about 1.2-1.5.

6. The influence of fuel on SNCR

When the boiler fuel is used, the denitrification efficiency obtained by SNCR unit is slightly different. When using coal as fuel, the ash content is high, and the ash is often rich in alkali metal oxides, CaO, Fe2O3 and other active substances. Research shows that CaO and Fe2O3 in the ash can promote the reaction of NOx and C to form N2 at high temperature and reduce the concentration of NO and N2O in the flue gas; moreover, the active substances in the recycled materials such as CaO and Fe2O3 have a multiphase catalytic effect on the reaction between NH3 and NO, which promotes the reaction, so the denitrification rate of SNCR is higher when using coal as fuel.

7. Flue gas atmosphere

O2, CO, H2O, H2, CHx and other components in the flue gas have a certain effect on the denitrification reaction.

In the absence of oxygen, SNCR reaction does not occur. It takes the presence of oxygen for the SNCR reaction to take place, while the rise in oxygen concentration shifts the temperature window of the reaction toward the low temperature and the maximum denitrification rate decreases. At low temperatures, when the concentration of water vapor is low, it is a promoter of the reduction reaction, and at high concentrations it is an impediment to the reaction. the increase in CO concentration shifts the temperature window of SNCR to low temperatures, the optimum temperature for denitrification decreases, and the denitrification rate decreases.

8. Initial NOx concentration

The initial NOx content also has an effect on the reduction efficiency, and the reduction of the initial NOx concentration leads to the reduction of the reactants. Under the condition of lower reactant concentration, the optimum temperature decreases, so the reaction efficiency also decreases. It has been shown that there is a critical concentration of NOx, and if the initial concentration of NOx is less than this critical value, then no matter how to increase the ammonia to nitrogen ratio, NOx cannot be removed. at the same time, the initial concentration of NOx is high, the temperature window of the reaction shifts to the right. The initial concentration is between 200-300mg/Nm3 and the denitrification efficiency is the highest.

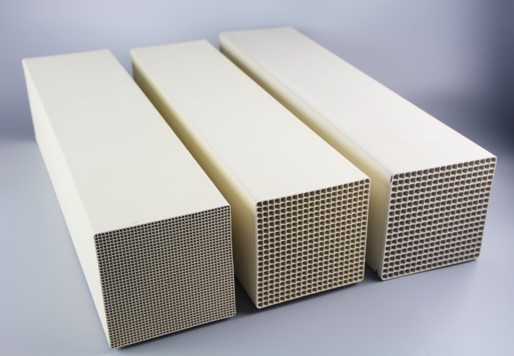

SCR denitrification system and SNCR denitrification system are two widely used methods in flue gas treatment at this stage, the main difference between them is that SCR denitrification system uses SCR denitrification catalyst, which has higher denitrification efficiency.

Anhui Yuanchen Environmental Protection S&T Co., Ltd (hereinafter referred to as "Yuanchen Technology") is a high-tech enterprise integrating R&D, production and sales of dust removal filter bags and denitrification catalysts. Over the past sixteen years, Yuanchen Technology has been focusing on the environmental protection field, and now has 4 international PCT, 33 authorized invention patents and 77 invention patents in process, among which many products such as "dust removal and denitrification integrated technology products" have been awarded the Scientific Progress Award of Anhui Province. Our dust filter bags and SCR denitrification catalysts have been widely used in cement, steel, glass kilns, waste incineration, biomass power generation, non-ferrous metal smelting and other industries.