The SCR flue gas denitrification catalyst is an important part of the SCR denitrification process, under the action of which selective catalytic reaction with NOx in the flue gas produces N2 and H2O. SCR flue gas denitrification technology has high denitrification efficiency, is mature and reliable, widely used, economical and reasonable, and highly adaptable, especially suitable for coal-fired units in areas with variable coal quality, frequent unit load changes and sensitive air quality requirements. It is especially suitable for coal-fired units with variable coal quality, frequent load changes and sensitive air quality requirements.

Catalyst performance indicators include process performance indicators (denitrification efficiency, SO2/SO3 conversion rate, NH3 escape rate, pressure drop), chemical composition content, geometric properties (pitch/spacing, specific surface area, porosity and specific pore area, average pore size and pore size distribution) and mechanical strength parameters. The better the chemical properties of the catalyst, the higher the efficiency of NOx removal from flue gas.

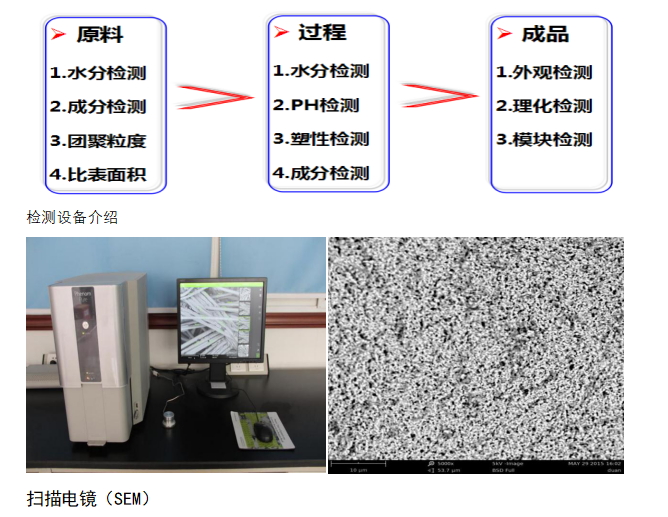

High quality products, in addition to advanced production technology and first-class production equipment, must strengthen quality control. We start to check the quality from the acceptance of raw materials, to a series of quality control during the process, and then to the final quality inspection and testing of finished products, to ensure that every product we manufacture is an excellent product.

Yuanchen Technology imported PHENOM PURE Scanning Electron Microscope (SEM) from Holland. This electron microscope can image 30s, realize 20x-20,000x continuous magnification, and the resolution is better than 30nm, which can be used to observe the surface morphology of newly made catalysts and spent catalysts, and can analyze the cause of catalyst deactivation. The catalyst in use can be observed and analyzed to develop a catalyst management plan.

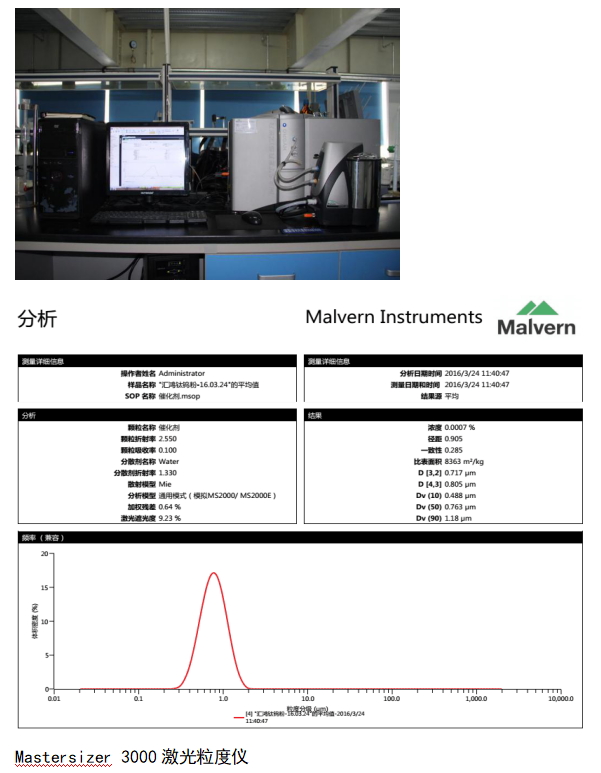

Based on laser scattering technology to characterize the particle size of particle samples, the particle size test range of 0.01-3500um can test the size of the dust of the bid project conditions and control the particle size of the catalyst raw material.

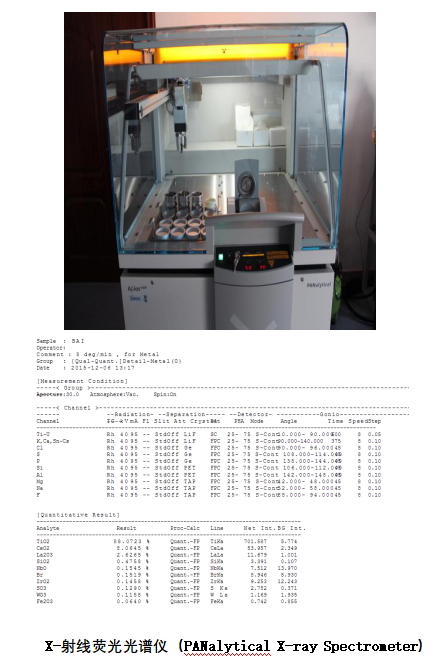

X-ray fluorescence spectrometer, capable of analyzing all elements between F(9) to U(92). The label-free semi-quantitative method can analyze various shapes of samples qualitatively and give semi-quantitative results, and the accuracy of the results can be close to the quantitative level for some samples with short analysis time. It can test the composition of active substances in catalysts to control product quality; it can also test soot composition or plugging ash composition to analyze the deactivation principle; it can also test and analyze samples from customers.

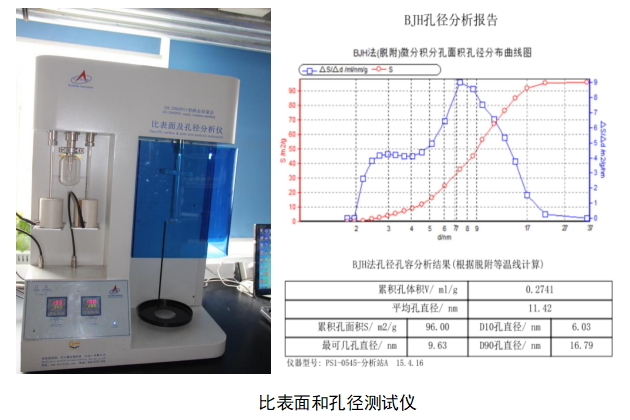

The specific surface area and pore size analyzer can study the nature of the surface and pores through the adsorption isothermal curve and calculate the specific surface and pore size distribution. It can be used to test the specific surface area and pore size of raw materials to ensure the stability of raw materials; it can test the specific surface area and pore size of finished products to ensure the specific surface area of finished products and thus the denitrification performance of finished products; it can test the specific surface area and pore size of spent catalysts to guide how to regenerate spent catalysts.

High-performance Fourier infrared spectrometer, with advanced instrument control technology, operation mode and analysis functions, material structure detection and analysis is mainly used for material identification: identification of raw material components, strict control of raw material quality.

Anhui Yuanchen Environmental Technology Co., Ltd (hereinafter referred to as "Yuanchen Technology") is a high-tech enterprise integrating R&D, production and sales of dust bag and denitrification catalyst. Over the past sixteen years, Yuanchen Technology has been focusing on environmental protection field, and now has 4 international PCT patents, 26 authorized invention patents, 60 utility model patents, 21 software copyrights, 27 drafted and participated standards, 1 national achievement appraisal, and 17 new products in Anhui Province. Among them, many products such as "dust removal and denitrification integrated technology products" were awarded the Scientific Progress Award of Anhui Province. The dust removal bags (mainly PPS, PTFE, P84 and composite series filter materials) and SCR denitrification catalysts have been widely used in cement, steel, glass kilns, waste incineration power generation, biomass power generation, non-ferrous metal smelting and other industries.

In the future, Yuanchen Technology will be guided by "becoming the guardian of global ecological environment", always rooted in environmental protection, and insist on the great cause of guarding the blue sky and white clouds. Leveraging on the national ecological civilization construction pattern, we will continue to deepen technology, optimize management, strengthen brand, refine industry and solidify advantages, and create synergistic value for industry through comprehensive and integrated governance and services.