The project design

System to effect

Maintenance instructions

Free testing

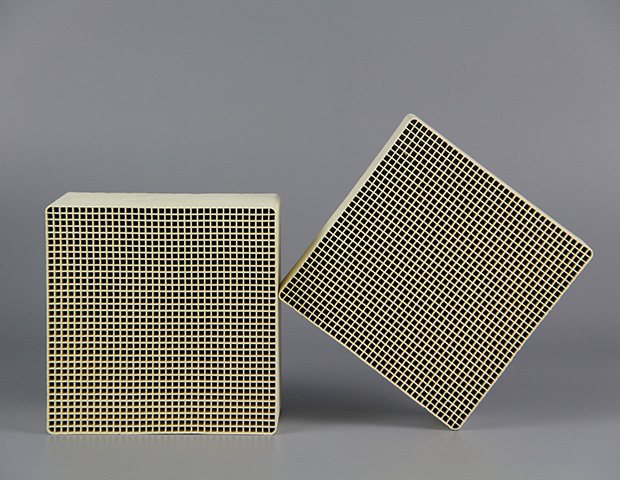

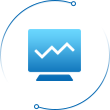

Non-electric fields such as sintering machines in the steel industry, coke ovens in the coking industry, waste incinerators, biomass power incinerators, etc., produce a variety of pollutants such as SOx, NOx, HCI, HF, dioxins, dust, etc. under high temperature combustion conditions, and their main characteristics include large flue gas volumes, temperature fluctuations, high dust concentrations, high gas corrosiveness, high SOx emissions, etc., and currently in these industries, the mature process is mostly denitrification between 180~300℃. For the flue gas conditions and denitrification difficulties in the non-electric sector, we design and manufacture homogeneous composite high-performance medium/low temperature denitrification catalysts, which are capable of highly efficient NOx and dioxin removal from flue gas under complex working conditions, with the commonly used honeycomb catalyst pores of 25, 30 and 35 holes.

The principle is as follows:

1. ammonium bisulfate poisoning at low temperature:On the one hand, the kinetic mechanism of SO2 and NH3 isolated adsorption on the catalyst surface was established by improving the structural properties of the carrier, regulating the chemical environment of the carrier surface, pore structure, and constructing the directional distribution of microscopic acid-base centers; on the microscopic scale, it makes the SO2 adsorption center far away from the catalytic active center and reduces the oxidation rate of SO2 on the macroscopic scale; on the other hand, the Through the optimization of the formulation, the activation energy of the decomposition of ammonium bisulfate is reduced to accelerate the decomposition of the already produced ammonium bisulfate.

2、Activity of catalyst at low temperature: Using the principle of metal solid solution and multi-metal effect, the cross-arrangement of different metal oxide molecules is realized, combined with the optimization of microscopic pore size, which ensures that the product can still have high activity between 170-300℃.

3. NOx and dioxin synergistic denitrification technology: While enhancing the low temperature activity of the catalyst, the optimized modification of catalyst composition and multi-path coupling technology enable the catalyst to have good dioxin removal function while denitrifying at low temperature.

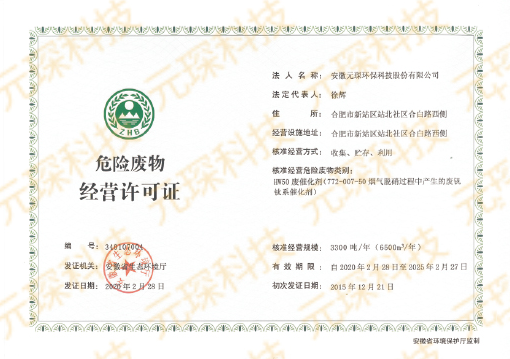

At present, the product has obtained provincial high-tech product certification and several invention patents (ZL201510427867.X A denitrification catalyst for dioxin removal and its preparation method, etc.), and the product has obtained dozens of low-temperature application cases in different non-electric fields.

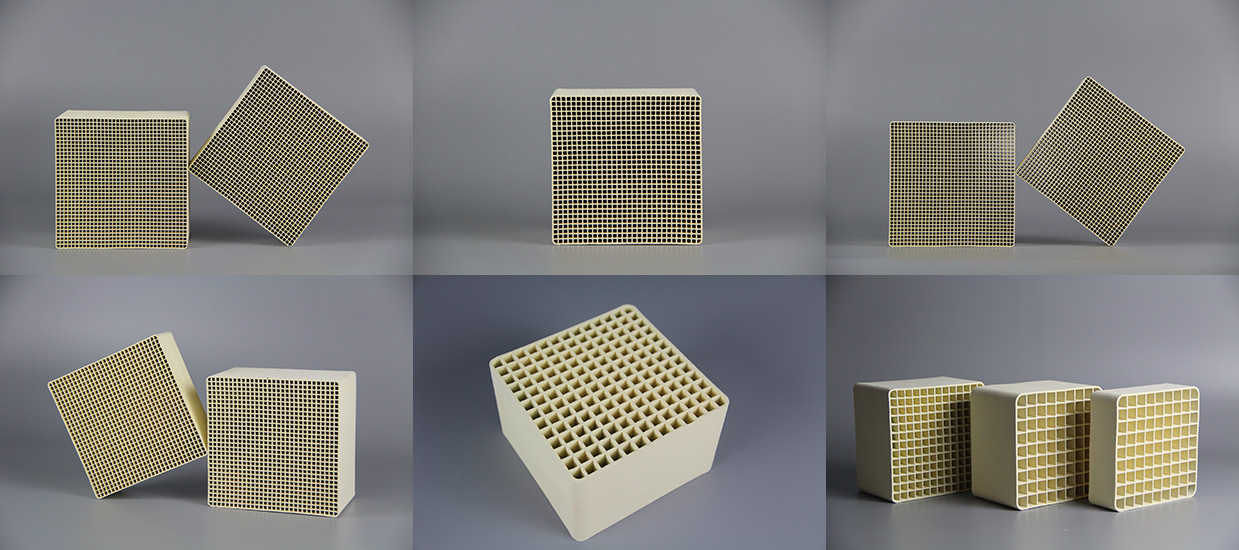

Using Japan's advanced production technology, according to the domestic coal quality and flue gas characteristics of optimization and upgrading, combined with independent research and development, the production of domestic different conditions of flue gas denitrification catalyst

By comparing catalyst composition, compressive strength, specific surface area, pore size analysis and activity detection in CNAS testing center, the cutting-edge catalyst performance enhancement technology with high activity, high wear resistance and high specific surface area was introduced