Polaris Atmosphere Network: I. Introduction

Ecological governance, the road is long and obstructed, the line will come. Since the implementation of the "Action Plan for the Prevention and Control of Air Pollution", China's pollution control efforts, the frequency of the introduction of the system, the scale of strict supervision and enforcement, the speed of environmental quality improvement, unprecedented. Pollutants produced in the flue gas of thermal power plants include sulfur oxides, nitrogen oxides, dust and other harmful components, especially nitrogen oxides combined with water in the air will eventually be converted into nitric acid and nitrate, nitrate and acid is one of the main components of acid rain, and under certain conditions will also produce photochemical smog pollution with other pollutants. In order to meet the requirements of ultra-low emission, Yuanchen Technology has allocated a large amount of scientific research funds and cooperated with famous universities in China to conduct development experiments and develop a kind of integrated filter media based on ceramic fiber for dust removal and denitrification.

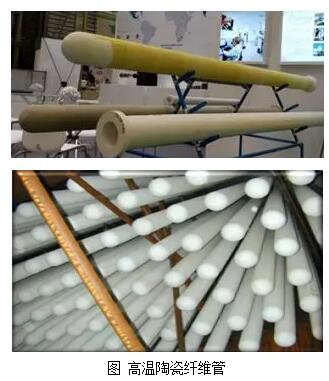

Common ceramic fiber, also known as aluminosilicate fiber, is an industrial product with the advantages of light weight, high temperature resistance, good thermal stability, low thermal conductivity, small specific heat and resistance to mechanical vibration, which can be used in various high temperature, high pressure and easy to wear environment.

Technical advantages

A kind of integrated filter media based on ceramic fiber for dust removal and denitrification" combines the advantages of the mature "dry desulfurization + integrated dust removal + SCR denitrification" process, while avoiding the disadvantages of this technology. The optimized porosity is made by a special filter tube production process, which provides effective surface filtration and allows for easier release of dust from the surface, with advanced patented technology for handling very high dust loads and maintaining low pressure drop. At the same time, the composite structure of the ceramic fiber filter tube avoids the flexibility of the bag, resulting in a better dust removal effect, while avoiding the hidden problem of gluing the bag, and its life span can reach 5-8 years, which is much better than the filter bag life span.

This technology has the following advantages compared with the prior art.

1, simultaneous removal of particulate matter, NOx, dioxins, combined with ceramic fiber filter and denitrification de-dioxin catalyst, in a set of equipment to achieve perfect high efficiency performance, where the dust filtration efficiency can reach more than 99.99%, NOx removal efficiency can reach more than 95%, dioxin removal efficiency can reach more than 99%.

2、Better economic efficiency: it can save about 25-35% of the overall cost.

3. Reliable and high efficiency: NOx efficiency can reach over 95%; dioxin efficiency can reach over 99%; particulate matter concentration in the exhaust is less than 5mg/Nm3 while the catalyst is still protected from catalyst poisoning and/or deactivation because it is incorporated into the filter wall, which is a great advantage over conventional honeycomb SCR systems. This is a very significant advantage over conventional cellular SCR systems. The catalyst remains active within the filter wall for several years, without any need to restore proven long-term performance.

4、Long product life: The ceramic fiber-based filter media is significantly better than conventional filter media in terms of high temperature resistance (the media itself can withstand 900°C), flame retardancy and corrosion resistance, while the surface of the filter media can effectively block metals such as arsenic, selenium and sodium that are harmful to the catalyst, significantly extending the service life of the catalyst.

5, energy saving: the addition of catalyst filter media can also be treated up to 350 ℃ exhaust gas, the output of very clean hot air for other uses in the plant, reducing the energy consumption of the heat exchanger.

By impregnating the ceramic fiber filter tube with titanium dioxide particles containing catalytic components, it has the advantage of catalytic reduction of NOx and dioxins in the flue gas while removing dust from the flue gas, and the combination of ceramic fiber filter and denitrification and dioxin catalyst achieves perfect high efficiency performance in one set of equipment, where the dust filtration efficiency can reach over 99.99%, NOx removal efficiency can reach The dust filtration efficiency can reach more than 99.99%, NOx removal efficiency can reach more than 95%, and dioxin removal efficiency can reach more than 99%, which can save about 25-35% of the overall cost, reliable and high efficiency, energy saving and long product life.

III. Conclusion

The traditional flue gas treatment system has many processing steps, large and numerous equipment, large floor space, and large corporate investment; the cost of post-operation is high, for example, due to the use of high-temperature electric dedusting, the electrodes are often covered with dust and need to be cleaned frequently; the calcium carbonate, calcium sulfite, and calcium sulfate waste generated by the desulfurization process requires solid waste treatment.

In contrast, the ceramic fiber filter tube integrated denitrification and dust removal system is the integration of de-dioxin, denitrification and dust removal, which only takes up 1/3 of the traditional flue gas treatment system due to the reduction in the number and volume of equipment, more centralized and compact due to the reduction in treatment steps.

Therefore, as a new technology applied in the field of air pollution control, the integrated denitrification and dedusting system of ceramic fiber filter tube has a good promotion and application value in various industries as an integrated synergistic treatment and treatment technology of de-dioxin, denitrification and dedusting at the same time. It is especially suitable for new glass production lines, but also for other industrial fields such as cement and waste incineration.

As an environmental protection enterprise, Yuanchen Technology has accumulated rich experience in industrial dust removal and denitrification, waste denitrification catalyst regeneration and other fields, and has occupied an important position in the air pollution treatment industry. In the future, Yuanchen Technology will, as always, respond to the national call to fight the battle for blue sky and make its due contribution to the protection of blue water and blue sky and the construction of beautiful China.