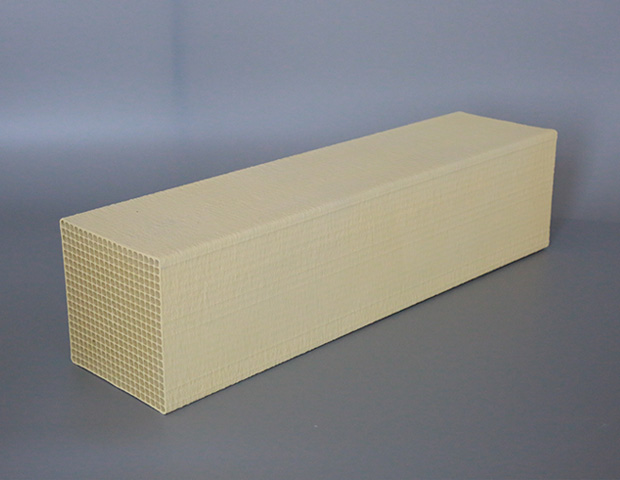

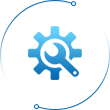

孔数:15孔、16孔、18孔、20孔

Service Hotline: 17333203296

Online consulting

The project design

System to effect

Maintenance instructions

Free testing

| SCR denitrification catalyst for power industry | |

| Flue gas characteristics |

The flue gas temperature after SCR is generally 300-420°C, which is in line with the conventional catalyst operation temperature. The concentration of dust in the flue gas is relatively high, up to 10-60g/Nm3; and it is mostly silicon and aluminum, etc., which causes more serious scouring and wear to the catalyst. High concentration of sulfur dioxide in the flue gas due to the different use of coal, which affects the catalyst service life. |

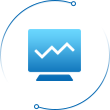

| Product characteristics | The catalyst needs to meet the high strength anti-scouring, large pore size anti-clogging, high resistance to alkali, high resistance to sulfur and other anti-poisoning ability |

| Product parameters | |

| Number of holes | 15 holes, 16holes, 18holes, 20holes |

| Abrasion resistance strength | Hardened end ≤ 0.06 (%/kg); non-hardened end ≤ 0.09 (%/kg) |

| Compressive strength | Axial compressive strength ≥ 2.8MPa; radial compressive strength ≥ 0.9MPa |

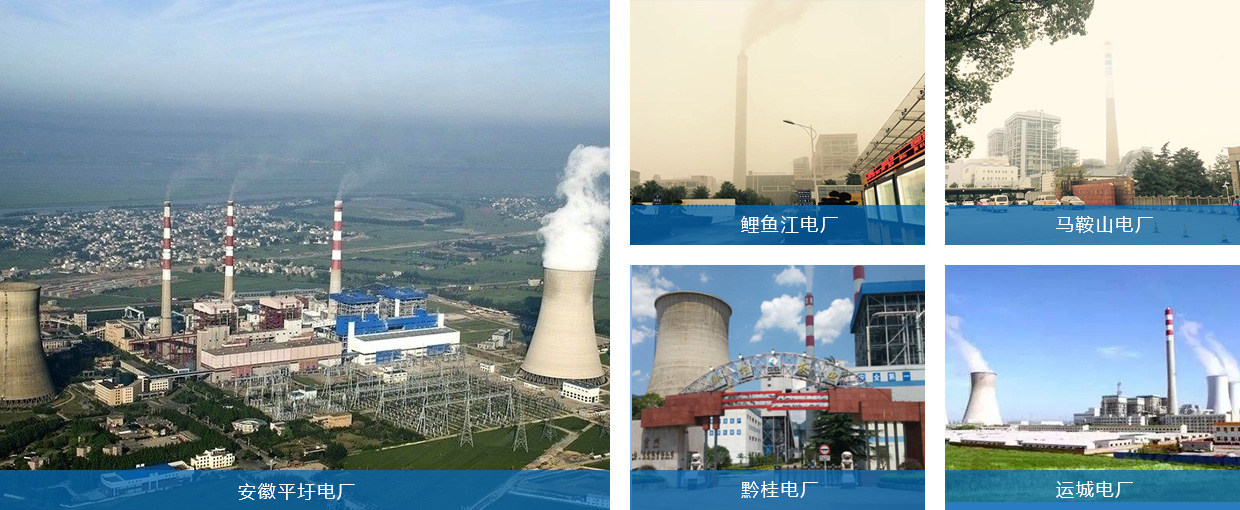

Using Japan's advanced production technology, according to the domestic coal quality and flue gas characteristics of optimization and upgrading, combined with independent research and development, the production of domestic different conditions of flue gas denitrification catalyst

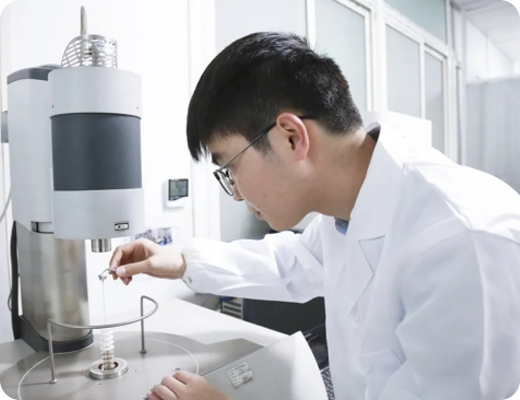

By comparing catalyst composition, compressive strength, specific surface area, pore size analysis and activity detection in CNAS testing center, the cutting-edge catalyst performance enhancement technology with high activity, high wear resistance and high specific surface area was introduced