Denitrification Catalyst Series | Introduction to the basics of V/Ti-based denitrification catalysts (I)

Most of the denitrification catalysts used in SCR are made of TiO2 as the carrier and V2O5 or V2O5-WO3 or V2O5-MoO3 as the active ingredient, and are made into three types of honeycomb, plate or corrugated type. SCR denitrification catalysts used in flue gas denitrification can be divided into high temperature catalysts (345℃~590℃), medium temperature catalysts (260℃~380℃) and low temperature catalysts (80℃~300℃), and different catalysts are suitable for different reaction temperatures. We can design and produce high, medium and low temperature denitrification catalysts according to customers' requirements, and they have been widely used in power industry and non-power industry.

I. Common raw materials and their functions of V/Ti catalyst

1. Titanium dioxide: carrier, defect (electron vacancy), large specific surface area, providing major acidic sites.

2. Silica: enhance wear resistance, strength additive, improve catalyst thermal stability.

3. ammonium metavanadate: provide V2O5, provide the main active material

4. ammonium metatungstate: provide WO3, auxiliary, anti-sulfur conversion, inhibit sintering.

5. glass fiber: structural additives, increase mechanical strength, prevent cracking and deformation.

6. Ammonia: regulates the acidity and alkalinity of the mud, which has high plasticity in alkaline state and is conducive to extrusion and molding.

II. Principle of V/Ti system catalyst denitrification

1. Basic reaction :

4NO+4NH3+O2→4N2+6H2O

2NO2+4NH3+O2→3N2+6H2O

2. Side effects:

SO2+1/2O2→SO3

NH3+SO3+H2O→NH4HSO4

2NH3+SO3+H2O→(NH4)2SO4

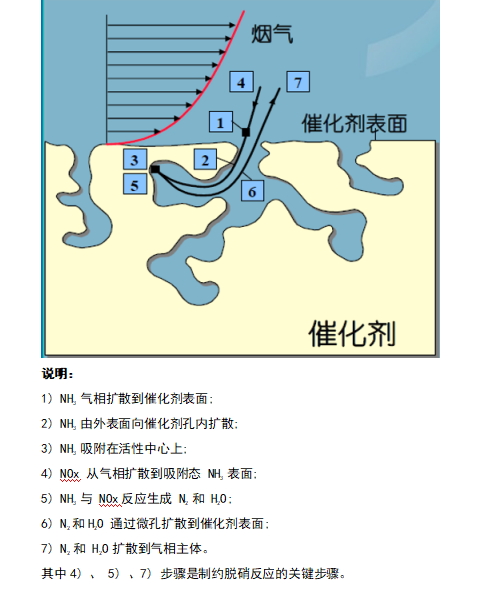

3. Reaction mechanism

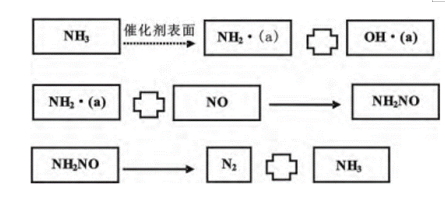

(1) ELEY-RIDEAL (E-R) mechanism

This means that a component of the reactant is chemisorbed on the catalyst surface and the reaction is carried out through the interaction of chemisorbed atoms or molecules with molecules in the gas phase (or physically adsorbed).

The acidic site is adsorbed to form NH3 in the ligand state, the NH2 group reacts with NO in the flue gas to produce NH2NO (nitrosamine), an important key intermediate in the denitrification process, and finally the intermediate NH2NO decomposes to form the final products N2 and H2O, and the active site regains activity by O2 oxidation.

2) LANGMUIR-HINSHELWOOD (L-H) mechanism

This is a multiphase catalytic mechanism in which the surface reaction is controlled by two adsorbed molecules. That is, the two reactants are first adsorbed on a solid catalyst, react on the surface, and the products are then desorbed. The surface reaction is the control step, and the adsorption and desorption rates are much faster than the surface reaction rate. The reaction rate is proportional to the coverage of the two reactants on the catalyst surface.

Unlike E-R mechanism, after adsorption of NH3, NO gas reacts with cavity oxygen on the catalyst surface to produce reaction intermediates containing -NO2 bonds, and then -NO2 intermediates combine with NH3 in the coordination state to produce NH4NO2 intermediates, and finally decompose to obtain the final products N2 and H2O.

Anhui Yuanchen Environmental Protection Technology Co., Ltd (hereinafter referred to as "Yuanchen Technology") is a high-tech enterprise integrating R&D, production and sales of dust bag and denitrification catalyst. Over the past sixteen years, Yuanchen Technology has been focusing on the environmental protection field, and now has 4 international PCT, 33 authorized invention patents and 77 invention patents in process, among which many products such as "dust removal and denitrification integrated technology products" have been awarded the Scientific Progress Award of Anhui Province. Our dust removal bags (mainly PPS, PTFE, P84 and composite series needle felt) and SCR denitrification catalysts have been widely used in cement, steel, glass kilns, waste incineration power generation, biomass power generation, non-ferrous metal smelting and other industries.

In the future, Yuanchen Technology will be guided by "becoming the guardian of global ecological environment", always rooted in environmental protection, and insist on the great cause of guarding the blue sky and white clouds. Leveraging on the national ecological civilization construction pattern, we will continue to deepen technology, optimize management, strengthen brand, refine industry and solidify advantages, and create synergistic value for industry through comprehensive and integrated governance and services.