White pollution is along with human social and economic development process is facing a huge challenge, the 21st century, the global rise of biodegradable trend, a number of countries issued a tightening policy to promote the development of the industry.

In December 2007, the Chinese government issued a "notice on the restriction of the production and sale of plastic shopping bags", which stipulates that since June 1, 2008, the production, sale and use of plastic shopping bags less than 0.025 mm thick are banned nationwide, and the implementation of plastic shopping bags paid use system.

April 2015 revised "People's Republic of China Solid Waste Pollution Prevention and Control Law" provides that: the state encourages scientific research, production units to research and produce film coverings and commodity packaging that are easy to recycle, easy to dispose of or degradable in the environment; units and individuals using agricultural films, should take measures such as recycling to prevent or reduce the pollution of the environment by agricultural films.

In April 2018, the Party Central Committee and the State Council issued the "Guidance on Supporting Hainan's Comprehensively Deepening Reform and Opening-up" to completely ban the production, sale and use of disposable non-degradable plastic bags and plastic tableware in Hainan, and accelerate the application of green packaging in the express delivery industry.

In January 2020, the "Opinions on Further Strengthening Plastic Pollution Control" (hereinafter referred to as "plastic ban") was issued, requiring the orderly prohibition and restriction of the production, sale and use of some plastic products, and actively promote alternative products, officially from "plastic restriction" to "plastic ban". to a "ban on plastic".

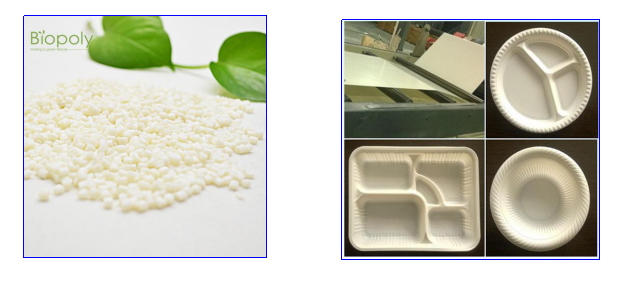

It has become the consensus of more and more national or local governments to restrict or ban the use of disposable plastic products through environmental protection legislation, which will also help promote the sustainable, stable and healthy development of lactic acid and polylactic acid industry. Polylatic acid (PLA), for short, is a thermoplastic polymer made from the polymerization of lactic acid produced by biological fermentation, which is also a kind of polyester material. PLA is an ideal green and renewable polymer material.

Polylactic acid production is based on lactic acid as raw material, most of the traditional lactic acid fermentation with starchy raw materials, currently the United States, France, Japan and other countries have developed the use of agricultural by-products as raw material fermentation production of lactic acid, and then the production of polylactic acid.

Production process method

(1) Direct polycondensation method

Polycondensation is the direct condensation of lactic acid monomers, also known as one-step polymerization method. In the presence of a dehydrating agent, the hydroxyl and carboxyl groups in the lactic acid molecule are dehydrated by heat and directly condensed to form an oligomer. By adding a catalyst and continuing to increase the temperature, the low relative molecular weight PLA is polymerized into a higher relative molecular weight PLA.

(2) Two-step process

The lactic acid is made into a cyclic dimer, propyleneglycolate, and then the ring is opened and condensed into PLA. This technology is more mature, and the process used by NatureWorks in the United States to produce PLA is this process. China's Haisheng and the Chinese Academy of Sciences jointly developed polylactic acid production technology is similar to this, the main process is the raw materials through microbial fermentation to produce lactic acid, and then through refining, dehydration oligomerization, high-temperature cracking, and finally polymerization into polylactic acid.

(3) Preparation of high molecular weight polylactic acid by reaction extrusion

Continuous melt polymerization experiments using a combination of an intermittent stirred reactor and a twin-screw extruder can yield PLA with a molecular weight of 150,000 made from lactic acid by continuous melt polycondensation. Higher molar mass PLA was prepared by further polycondensation of low molar mass lactic acid prepolymer on an extruder using a twin-screw extruder. The molar mass of PLA could be quickly and effectively increased by twin-screw reactive extrusion polycondensation at a reaction temperature of 150 °C, a catalyst dosage of 0.5%, and a screw speed of 75 r/min, and the dispersion coefficient of the reactive extruded product was reduced and the homogeneity became better. The comparison of DSC curves revealed that the crystallinity of PLA produced by reactive extrusion polycondensation was reduced, which was useful for improving the brittleness of PLA materials exhibiting large brittleness in use.

PLA production process

1) Material extraction

Shell crops such as corn are milled and starch is extracted from them, and then the starch is made into unrefined glucose. Many high technologies have overcome the process of subtracting the crushing and extracting the raw materials directly from a large number of crops.

2) Fermentation

Fermentation of glucose in a manner similar to the production of beer or alcohol, and the fermentation of glucose into lactic acid similar to that added to food for use in human muscle tissue.

3) Intermediate product

The lactic acid monomer is converted into an intermediate product, anhydrous lactic acid, or propanediol, by a special concentration process.

4) Polymerization

After vacuum purification of the propyleneglyceride monomer, a solvent-free dissolution process is used to complete the ring-opening process and polymerize the monomer.

5) Polymer Modification

Since the molecular weight and crystallinity of polymers are different, there is a lot of room for variation in material properties, so PLA is modified in different ways for different applications.

PLA can be hydrolyzed to lactic acid in human body, and the end product is non-toxic carbon dioxide and water, so PLA is a biodegradable medical material approved by FDA, and PLA products can be used in 3D printing and household products. In the field of bio-medical applications, PLA products can be used in drug slow release systems, medical sutures, artificial dressings, tissue engineering materials, etc. In the field of 3D printing, PLA products are mainly used as 3D high performance consumables, which promote the rapid development of 3D printing; in the field of daily household products, PLA products can be used as packaging wet wipes, non-woven fabrics, space cups, disposable lunch boxes, etc.