Denitrification catalysts are broadly defined as catalysts in SCR denitrification systems in power plants. In the SCR reaction, substances that induce a chemical reaction between the reducing agent and the nitrogen oxides in the flue gas selectively at a certain temperature. The use of denitrification catalysts can effectively improve the efficiency of nitrogen oxide removal.

A complete SCR system requires a reactor, catalyst, ammonia storage and injection system. Because of the pressure drop of the gas through the SCR reactor, additional fan capacity in the boiler or additional fans may be required. The liquid ammonia is transported by tanker truck to the liquid ammonia storage tank, where the liquid ammonia output is atomized and mixed with air and injected into the catalyst reactor through the nozzles of the ammonia injection grid. After the reaction temperature is reached and the exhaust gas is fully mixed with ammonia, the ammonia flows through the catalyst bed of the SCR reactor, where the ammonia reacts with NOx in a catalytic redox reaction, reducing NOx to harmless N2 and H2O.

Both liquid ammonia and ammonia water can be used as the reducing agent for SCR reaction. Liquid ammonia is almost 100% pure ammonia, which is a gas at atmospheric pressure and must be transported or stored under pressurized conditions. ammonia used as a reducing agent in SCR systems is commonly transported and stored at 29.4% ammonia. Compared to liquid ammonia, there are no safety issues with ammonia for transportation and storage, but larger containers are required for storage. When 29.4% ammonia is used as the reducing agent, an evaporator is required for the SCR system to provide a sufficiently high ammonia vapor pressure. The cost of reducing agent consumption affects the operating cost of the SCR system.

One of the issues of concern for the SCR process is the generation of solid ammonium sulfate and liquid ammonium bisulfate downstream of the reactor. Due to the presence of some unreacted NH3 in the SCR system and the generation of some SO3 from the combustion of sulfur-containing fuels, it is inevitable that substances such as ammonium sulfate are generated, which reacts as follows.

Ammonium sulfate and ammonium bisulfate are very fine particles that will condense and adhere when the temperature drops below 260°C. They can be deposited on the catalyst and its downstream air preheater, flue and fan, causing catalyst void plugging deactivation and corrosion of the air preheater, etc. To prevent the generation of ammonium sulfate and ammonium bisulfate, it is generally required to control the oxidation conversion of SO2/SO3 <1% and ammonia escape rate around 3ppm.

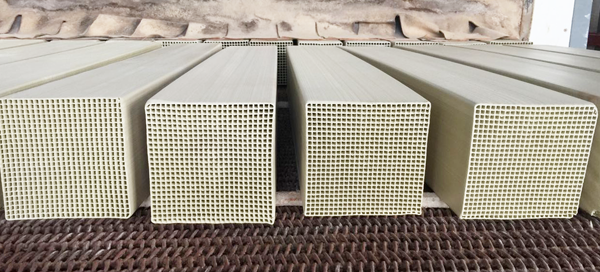

Anhui Yuanchen Environmental Technology Co., Ltd (hereinafter referred to as "Yuanchen Technology") is a high-tech enterprise integrating R&D, production and sales of dust removal bags and denitrification catalysts. Over the past sixteen years, Yuanchen Technology has been focusing on the environmental protection field, and now has 4 international PCT, 33 authorized invention patents and 77 invention patents in process, among which many products such as "dust removal and denitrification integrated technology products" have been awarded the Scientific Progress Award of Anhui Province. Our dust removal bags (mainly PPS, PTFE, P84 and composite series filter materials) and SCR denitrification catalysts have been widely used in cement, steel, glass kilns, waste incineration power generation, biomass power generation, non-ferrous metal smelting and other industries.

In the future, Yuanchen Technology will be guided by "becoming the guardian of global ecological environment", always rooted in environmental protection, and insist on the great cause of guarding the blue sky and white clouds. Leveraging on the national ecological civilization construction pattern, we will continue to deepen technology, optimize management, strengthen brand, refine industry and solidify advantages, and create synergistic value for industry through comprehensive and integrated governance and services.