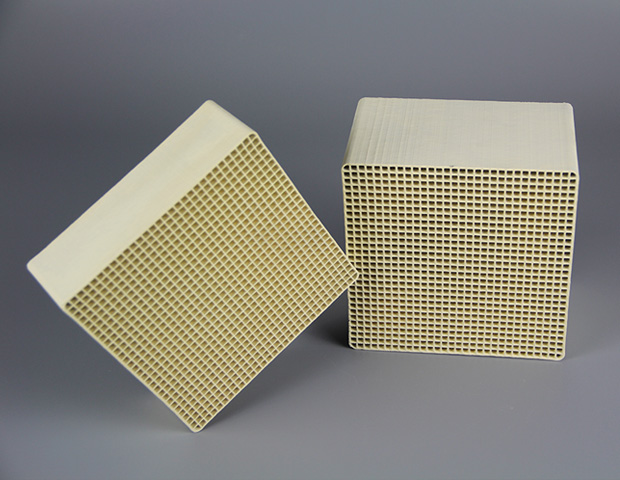

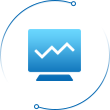

18孔、22孔、25孔、30孔

Service Hotline: 17333203296

Online consulting

The project design

System to effect

Maintenance instructions

Free testing

| SCR denitrification catalyst for steel industry (sintering/ pellet) | |

| Flus gas characteristics | The original flue gas temperature is low, generally at 120-150℃; SO2 concentration is high, the flue gas SO2 concentration is generally 1000-1500mg/m3, some can also reach 3000-5000mg/m3; the moisture content is high, can reach 10%-16%; the dust is sticky under high humidity and high sulfur conditions, easy to cause catalyst blockage; the dust composition is complex, containing K2O, Na2O, ZnO and other alkali/alkaline earth metal components. |

| Product characteristics | The catalyst needs to meet the performance of denitrification at low temperature, and needs to have high resistance to alkali, high resistance to sulfur and other anti-poisoning ability |

| Product parameter | |

| number of holes | 18holes, 22holes, 25holes, 30holes |

| Temperature range | 150℃-380℃ |

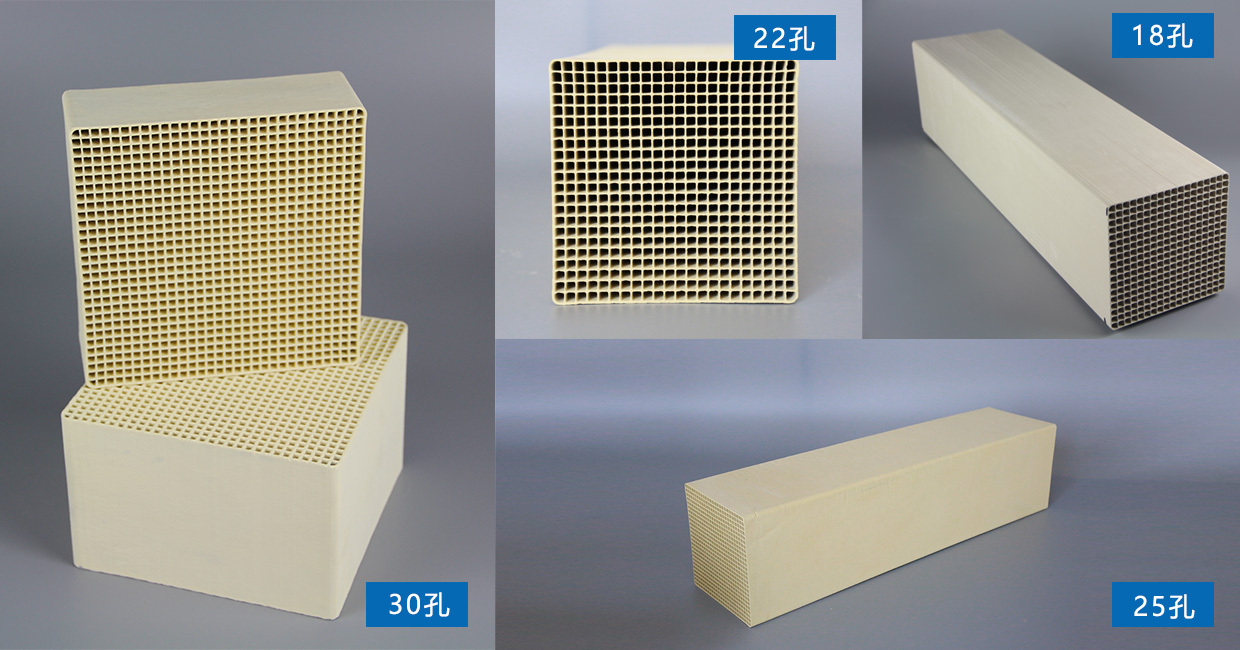

Using Japan's advanced production technology, according to the domestic coal quality and flue gas characteristics of optimization and upgrading, combined with independent research and development, the production of domestic different conditions of flue gas denitrification catalyst

By comparing catalyst composition, compressive strength, specific surface area, pore size analysis and activity detection in CNAS testing center, the cutting-edge catalyst performance enhancement technology with high activity, high wear resistance and high specific surface area was introduced