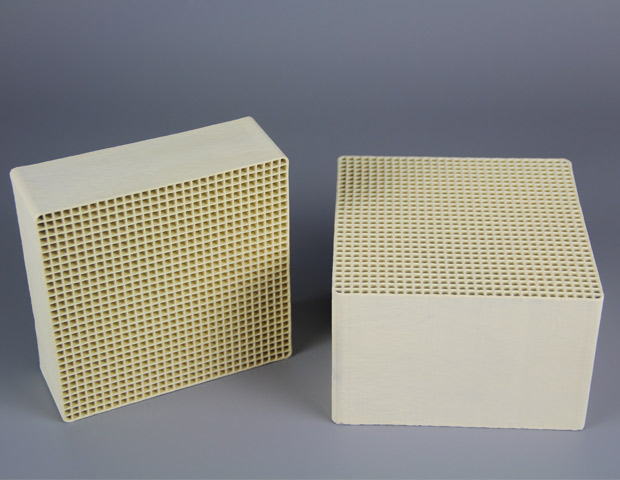

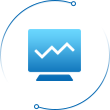

焦化 玻璃 化工 石灰窑 耐火窑 供暖/供气 孔数:20孔、22孔、25孔、30孔

Service Hotline: 17333203296

Online consulting

The project design

System to effect

Maintenance instructions

Free testing

| White Ash Kiln SCR denitrification catalyst |

Glass kiln SCR denitrification catalyst |

Coking Industry SCR denitration catalyst |

|

| Flus gas characteristics | White ash kiln flue gas temperature is low, generally around 140-220 ℃; flue gas water content is low, generally at 5%-8% (vol%); SO2 content is low, generally at <50mg/Nm3, but there are fluctuations; dust calcium content is extremely high, generally at around 60-80%. | High NOx content, glass melting process temperature up to 1500 ℃ or more, high temperature combustion generates a large amount of thermal NOx; change fire operation, flue gas volume and flue gas components fluctuate greatly; alkali metals, alkaline earth metals (Na salt, K salt, CaO, etc.) content is high, resulting in rapid loss of catalyst activity; small particle size of soot, strong adhesion and high corrosion, containing a variety of acidic gases (HCl, HF, etc.). | Coke oven flue gas temperature is low, higher than sintered pellets, generally around 200-260°C. The water content of flue gas is large, generally in the range of 12%-18% (vol%). Different fuels lead to different levels of NO content in coke oven flue gas, generally in the range of 300-1500mg/Nm3. SO2 content varies greatly from coke plant to coke plant. The SO2 content in coke oven flue gas is generally in the range of 50-800mg/Nm3. The dust content is low, generally in the range of 2O-50mg/Nm3. |

| Product characteristics | The catalyst needs to meet the denitrification activity under low temperature; it needs to meet the resistance to sulfur poisoning under low temperature; it needs to meet the resistance to alkali (calcium) poisoning. | The diversity of fuels (using fuels such as heavy oil, natural gas, coal gas, petroleum coke, etc.) leads to large differences in the composition of flue gas pollutants; the catalyst needs to meet the denitrification activity at low temperatures; it needs to meet the resistance to sulfur poisoning; it needs to meet the resistance to alkali poisoning; it has the ability to resist corrosion of acid gases. | The catalyst needs to meet the performance of denitrification at low temperature; it needs to have the ability to resist sulfur poisoning at low temperature; it needs to have the ability to resist water poisoning at low temperature. |

| Product parameter | |||

| Number of holes | 25holes, 30holes | 20holes, 22holes, 25holes | 25holes, 30holes |

| Temperature range | 150℃-380℃ | 150℃-380℃ | 150℃-380℃ |

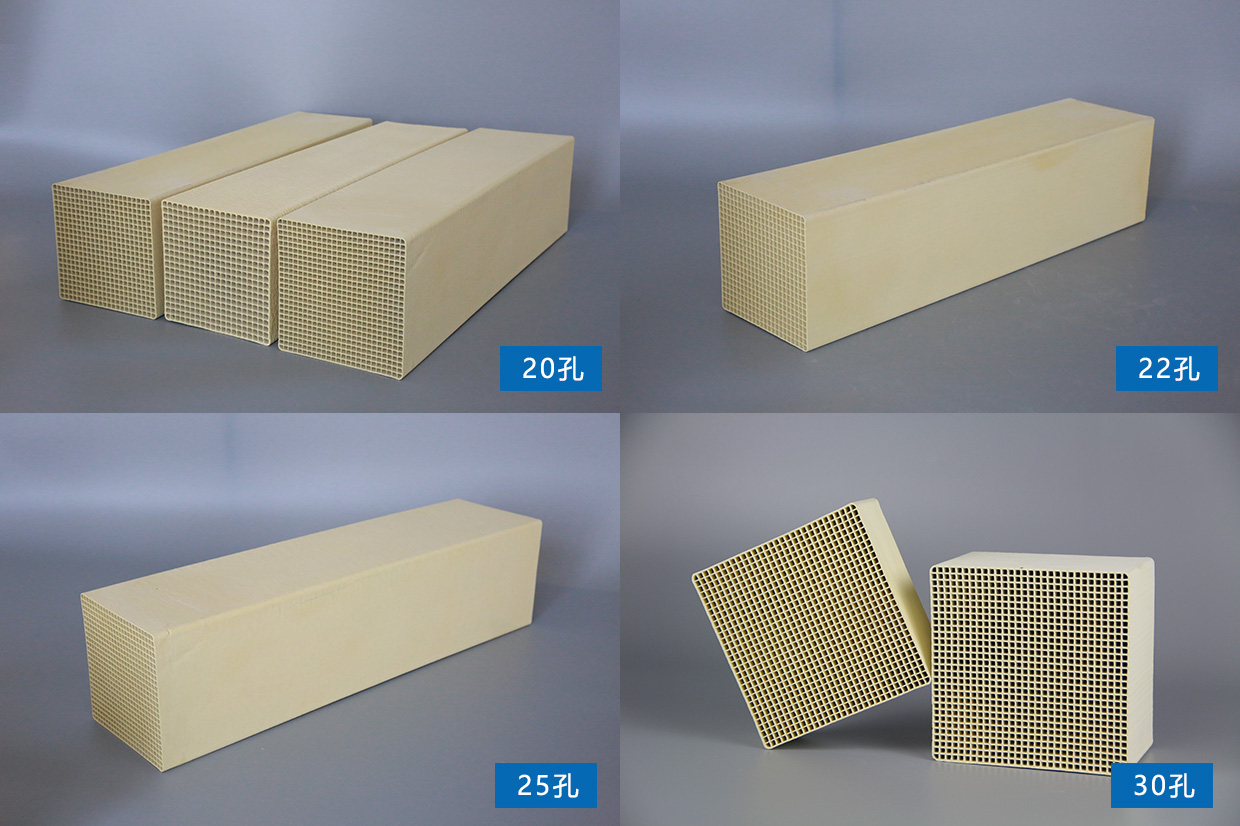

Using Japan's advanced production technology, according to the domestic coal quality and flue gas characteristics of optimization and upgrading, combined with independent research and development, the production of domestic different conditions of flue gas denitrification catalyst

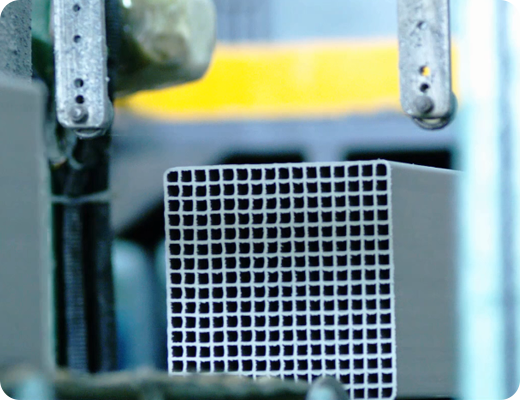

By comparing catalyst composition, compressive strength, specific surface area, pore size analysis and activity detection in CNAS testing center, the cutting-edge catalyst performance enhancement technology with high activity, high wear resistance and high specific surface area was introduced