The previous article introduced the common raw materials of SCR denitrification catalysts and their roles, as well as the reaction principles of denitrification catalysts, ELEY-RIDEAL (E-R) mechanism and LANGMUIR-HINSHELWOOD (L-H) mechanism. Today, we introduce you the conventional characterization tools for V/Ti-based denitrification catalysts.

There are ten main physicochemical characterization tools for SCR denitrification catalysts, according to which the performance of the catalyst can be understood and the catalyst properties can be judged.

1、X-ray diffraction (XRD) analysis

By performing X-ray diffraction on a material and analyzing its diffraction pattern, information such as the composition of the material, the structure or morphology of the atoms or molecules inside the material is obtained, which can be used to determine the atomic and molecular structure of a crystal.

It follows the Bragg equation: 2dsinθ=nλ; diffraction occurs only when the difference in the light range irradiated to two adjacent crystal surfaces is n times the wavelength of the X-rays.

The X-ray diffraction (XRD) analysis can confirm the catalyst substance type, good or bad crystalline shape, particle dispersion, calculated particle size (Scheele's equation) and lattice doping, formation of alloy or not (offset).

2、BET specific surface meter

BET can know the pore volume, pore size distribution and specific surface area of the sample and other related pore structure data.

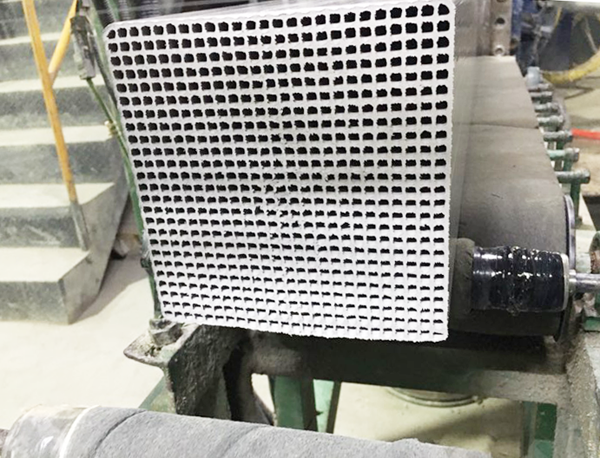

3、Scanning electron microscope (SEM)

Scanning electron microscope can observe catalyst morphology, particle size, dispersion, which can be accompanied by X-ray energy spectrum (EDX).

4、Transmission electron microscope (TEM)

Transmission electron microscope (TEM) can observe catalyst morphology, particle size, dispersion, crystal plane, crystal plane spacing (increase and decrease, lattice doping, alloy formation), etc., with high-resolution electron microscope picture (HRTEM), selected area electron diffraction spectrum (SAED) and X-ray energy spectrum (EDX)

5、X-ray photoelectron spectrometer (XPS)

Using this detection technique, we can perform component identification, valence analysis (valence ratio), elemental chemical environment analysis (offset), atomic ratio, and semi-quantification of samples.

6、H2-TPR programmed temperature rise reduction

The H2-TPR procedure can be used to confirm the reduction properties of oxides, metal-oxide interactions, metal-carrier interactions, reaction activation energy, etc.

7、NH3-TPD program warming desorption

NH3-TPD programmed temperature desorption can be used to analyze the number and density of acidic sites on the catalyst surface.

8、Fourier transform laser Raman spectroscopy (Raman)

The relationship between catalyst structure and SCR performance can be analyzed by Fourier transform laser Raman spectroscopy (Raman).

9、Infrared spectroscopy (FTIR) analysis

Using infrared spectroscopy (FTIR) can determine the acidic sites and their intensity, and determine the catalyst deactivation.

10、Resistance to water and sulfur

The water and sulfur resistance study can diagnose the catalyst's ability to resist poisoning.

Anhui Yuanchen Environmental Technology Co., Ltd (hereinafter referred to as "Yuanchen Technology") is a high-tech enterprise integrating R&D, production and sales of dust removal bags and denitrification catalysts. Over the past sixteen years, Yuanchen Technology has been focusing on the environmental protection field, and now has 4 international PCT, 33 authorized invention patents and 77 invention patents in process, among which many products such as "dust removal and denitrification integrated technology products" have been awarded the Scientific Progress Award of Anhui Province. Our dust removal bags (mainly PPS, PTFE, P84 and composite series needle felt) and SCR denitrification catalysts have been widely used in cement, steel, glass kilns, waste incineration power generation, biomass power generation, non-ferrous metal smelting and other industries.

In the future, Yuanchen Technology will be guided by "becoming the guardian of global ecological environment", always rooted in environmental protection, and insist on the great cause of guarding the blue sky and white clouds. Leveraging on the national ecological civilization construction pattern, we will continue to deepen technology, optimize management, strengthen brand, refine industry and solidify advantages, and create synergistic value for industry through comprehensive and integrated governance and services.