Denitrification catalyst is an important part of SCR denitrification system, which can effectively improve denitrification efficiency and realize ultra-low emission of flue gas management. Before this we shared a lot of basic knowledge about denitrification catalysts, so what is the SCR denitrification reactor like?

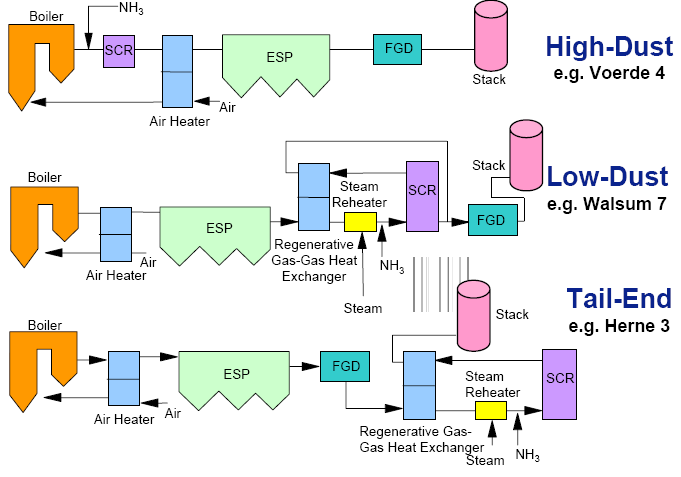

According to the relative position of SCR denitrification reactor installation, SCR system has three ways: high dust arrangement, low dust arrangement and tailing arrangement.

(1) High dust arrangement method

The SCR reactor is arranged between the boiler coal saver and air preheater, and the flue gas temperature is in the range of 300~400℃, which is the best reaction temperature for most metal oxide catalysts, and the flue gas does not need to be heated to obtain a high NOx purification effect. The life of catalyst in high dust flue gas will be affected by the following factors: (1) K, Na, Ca, Si and As in the fly ash will contaminate or poison the catalyst; (2) the fly ash will wear the reactor and clog the catalyst; (3) the high flue gas temperature will cause the catalyst to sinter.

(2) Low dust arrangement

The SCR reactor is arranged between the high temperature electric precipitator and air preheater after the coal saver, which can prevent the fly ash in the flue gas from polluting the catalyst and wearing and blocking the reactor. However, most of the electric precipitators cannot operate normally at high temperature of 300~400℃.

(3) Tail arrangement method

The SCR reactor is arranged after the dust collector and flue gas desulfurization system, the catalyst is not polluted by fly ash and SO3, etc. However, due to the low flue gas temperature of 50~60℃, a gas-gas heat exchanger (GGH) is generally required or a burner with fuel oil or natural gas is used to raise the flue gas temperature to the active temperature of the catalyst, which increases the energy consumption and operation cost.

Anhui Yuanchen Environmental Technology Co., Ltd (hereinafter referred to as "Yuanchen Technology") is a high-tech enterprise integrating R&D, production and sales of dust removal bags and denitrification catalysts. Over the past sixteen years, Yuanchen Technology has been focusing on the environmental protection field, and now has 4 international PCT, 33 authorized invention patents and 77 invention patents in process, among which many products such as "dust removal and denitrification integrated technology products" have been awarded the Scientific Progress Award of Anhui Province. Our dust removal bags (mainly PPS, PTFE, P84 and composite series needle felt) and SCR denitrification catalysts have been widely used in cement, steel, glass kilns, waste incineration power generation, biomass power generation, non-ferrous metal smelting and other industries.

In the future, Yuanchen Technology will be guided by "becoming the guardian of global ecological environment", always rooted in environmental protection, and insist on the great cause of guarding the blue sky and white clouds. Leveraging on the national ecological civilization construction pattern, we will continue to deepen technology, optimize management, strengthen brand, refine industry and solidify advantages, and create synergistic value for industry through comprehensive and integrated governance and services.